- COMPUTERIZED CONTROL UNIT

- BARCODE PRINTER

- SERVO CONTROLLED CUTTING UNIT

- 3 PIECES PANELS CUTTABLE AT THE SAME TIME

- 9 PIECES STANDARD HOLDER

- CUTTING DIMENSIONS IS (3.80×3.80 CM)

- AUTOMATIC ADJUSTABLE UP-DOWN AND FRONT-BACK OPTION

- REMOTE SERVICE CONNECTION

- SPEED ADJUSTMENT ACCORDING TO WIDTH OF MATERIAL

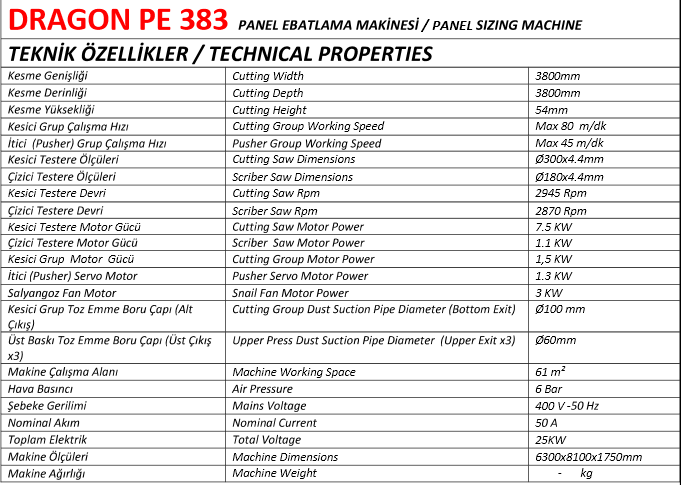

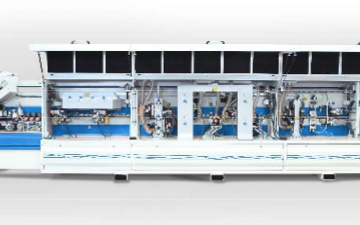

DESCRIPTION OF PANEL SIZE MACHINE – DRAGON PE 383

- 3800×3800 panel (max. 54 mm) cutting height optimization program, minimizes fast and waste calculations and makes the cut plan.

- It works with a program that guides the operator.

- Optional manual cutting.

- Optional single cutting feature. (On the x axis)

- The DRAGON PE 383 uses the KOP EXPERT operations program.

- The cutting group is controlled by the Servo reducer motor.

- The Movement of the cutting group is on the induction spindle, roller and control rack system.

- The movement of the cutting blade is handled by the pneumatic piston.

- With the integrated dust collector system on the cutting group (trolley), it ensures the evacuation of the dust and shavings that may occur during cutting by minimizing tossing out.

- Sriber cutter parallelism and cutting depth can be adjusted electronically by entering value on the panel.

- Ability to automatically adjust cutting speed according to material height.

- Mounted on the top of the unit there are 4 pieces (60 diameter) and 1 piece (100 diameter) dust vents are present.

- Dragon pe 383 has 3 air-cushioned. 2 fixed and 1 linear motion.

- The pusher group is controlled by servo motor and minimizes measurement errors with advanced bearing system and double sided bearing system with induction shaft control rack system.

- The pusher group comprise of 9 pressure pistons. Optionally can be increased to 11 pistons.

- The top press rollers prevent the material from moving by applying even pressure on the entire surface of the part with linear and rack mounting.

- Automatic top stop system is controlled by servo reducer motor.

- Barcode printer system.

- Useful and simple interface.

- Boot-start-stop feature for serial cuts without the need for a control panel.

- Top pressure and pusher air pressure gauge adjustment.

0 Comments